Heat Transfer Fluid: Vital for Enhancing Industrial Heating & Cooling Equipments

Heat Transfer Fluid: Vital for Enhancing Industrial Heating & Cooling Equipments

Blog Article

The Duty of Heat Transfer Liquid in Enhancing System Efficiency and Security

In the ever-evolving landscape of commercial processes, warm transfer fluids (HTFs) emerge as essential elements in optimizing both system efficiency and security. These specialized liquids, known for their remarkable thermal conductivity and controlled viscosity, make it possible for effective warm exchange, which is essential for structured operations.

Recognizing Warm Transfer Liquids

Heat transfer liquids, often thought about the lifeline of thermal administration systems, play a crucial role in managing temperature across numerous industrial applications - heat transfer fluid. Industries such as chemical processing, power generation, and production rely on warm transfer liquids to ensure equipment operates successfully and safely.

The choice of a suitable warm transfer fluid is vital to the success of a thermal administration system. In summary, a thorough understanding of warmth transfer fluids is important for enhancing system performance, guaranteeing operational safety, and achieving cost-effective thermal monitoring remedies.

Trick Characteristic of HTFs

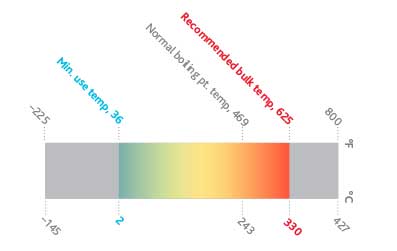

The details heat capacity of an HTF delineates the amount of warm power called for to transform its temperature level, impacting how successfully the system can react to temperature level variations. The boiling and freezing points of HTFs also play a critical function, particularly in systems subjected to severe temperature levels, making certain liquid security and protecting against stage adjustments throughout procedure.

Enhancing System Efficiency

To improve system performance with warmth transfer fluids (HTFs), it is vital to incorporate a detailed method that considers both liquid residential properties and system design. The option of an appropriate HTF is critical, as its thermal conductivity, thickness, and certain heat capability directly influence the efficiency of warmth exchange.

Just as vital is the design of the heat transfer system itself. The surface area and material of heat exchangers ought to be enhanced to make best use of warmth transfer efficiency.

Boosting Operational Safety

Ensuring operational safety in heat transfer systems needs a thorough concentrate on both the properties of heat transfer fluids (HTFs) and the design and upkeep of the whole system. HTFs have to have thermal security, low flammability, and suitable viscosity to lessen dangers such as leaks, fires, and system malfunctions. Picking the best HTF is important as it figures out the system's capability to deal with temperature fluctuations without compromising security.

The style of the system should incorporate redundancies and fail-safes to take care of possible dangers successfully. This consists of the combination of safety shutoffs, stress relief tools, and temperature level tracking systems to discover and address abnormalities immediately. Routine upkeep is important to ensure that all parts, including pumps, pipes, and seals, are operating properly and are without browse around this site wear or deterioration, which might lead to unsafe leaks or failings.

Moreover, personnel in charge of the operation and upkeep of warm transfer systems have to be appropriately learnt safety and security procedures and emergency situation action treatments. Constant training programs and safety drills can substantially lower the possibility of crashes, guaranteeing a more secure working atmosphere. Inevitably, an extensive technique to safety-- encompassing liquid selection, system style, and labor force training-- is indispensable for ideal operational security.

Market Applications of HTFs

Extensively utilized across numerous sectors, warm transfer liquids (HTFs) play a crucial function in boosting the performance and reliability of thermal monitoring systems. In the chemical industry, HTFs are important for keeping specific temperatures during reactions, making sure item uniformity and top quality. They facilitate heat exchange processes in reactors, condensers, and warmth exchangers, thus enhancing power usage and decreasing waste.

In the oil and gas field, HTFs are employed in both upstream and downstream operations. They manage temperature in drilling operations and improve efficiency in refining processes by supplying steady thermal view it now problems. This leads to reduced downtime and enhanced safety, particularly in vital operations such as distillation and breaking.

The sustainable energy sector also benefits dramatically from HTFs, specifically in concentrated solar energy (CSP) plants. Right here, HTFs transfer caught solar power to power generators, enabling reliable electrical energy generation. The pharmaceutical sector relies upon HTFs for exact temperature control in both synthesis and storage, ensuring item effectiveness and security.

Additionally, the food and drink field uses HTFs for pasteurization, sterilization, and food preparation processes, boosting both item safety check my site and manufacturing efficiency. Throughout these markets, HTFs act as vital components in keeping ideal functional performance and safety and security.

Final Thought

Warmth transfer fluids are important in enhancing commercial system efficiency and safety by using high thermal conductivity, ideal thickness, and thermal stability. Correct choice and upkeep of HTFs enhance heat exchange effectiveness, consequently enhancing functional effectiveness.

Report this page